De Stefani

& Figli S.R.L.

De Stefani & Figli srl has over forty years’ experience in injection and two-component moulding. Find out how we can meet your needs by visiting our production network.

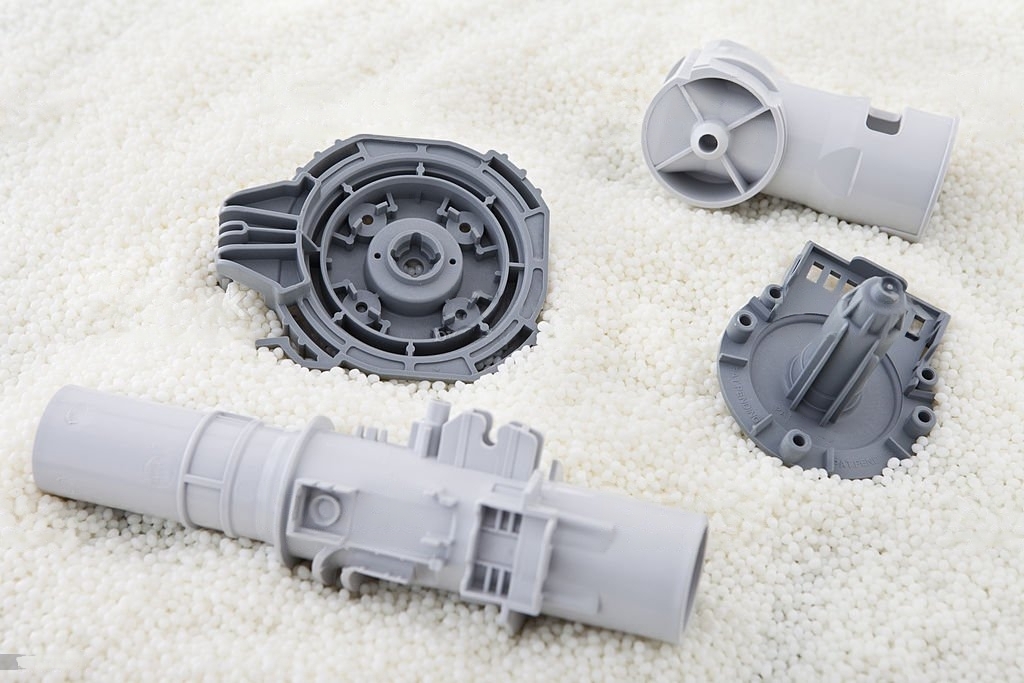

Specialised in thermoplastic injection and two-component moulding

Plastic injection moulding for over 40 years

De Stefani & Figli srl has worked in plastic injection moulding for over forty years, providing a level of service that has enabled it to grow continuously and establish itself on the market. The company was founded in 1980 as Valerio De Stefani Srl and was renamed De Stefani & Figli Srl in 2012 after the next generation of the family took over.

Production sectors

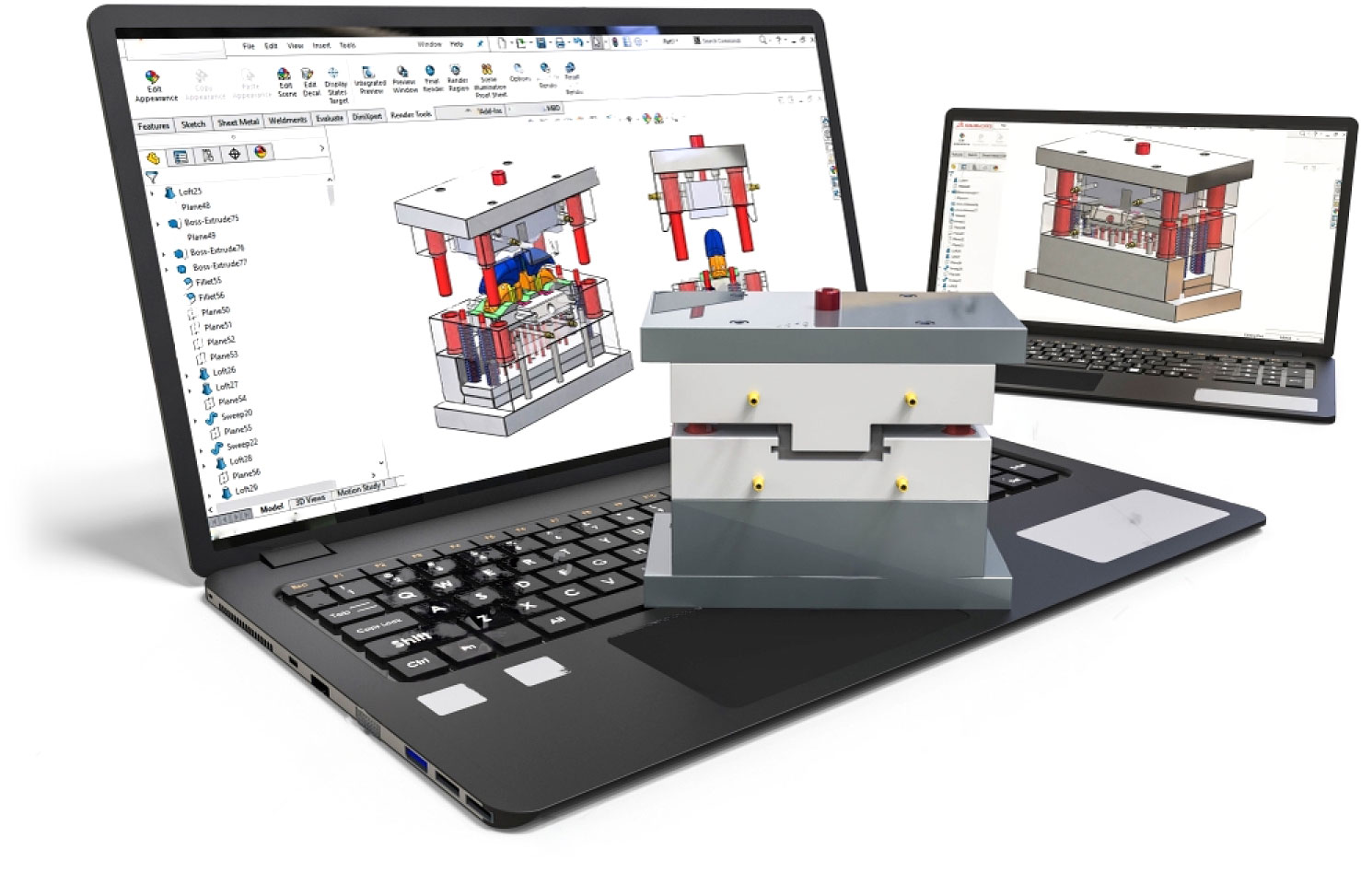

Design.

R&D technical dept.

Mould construction.

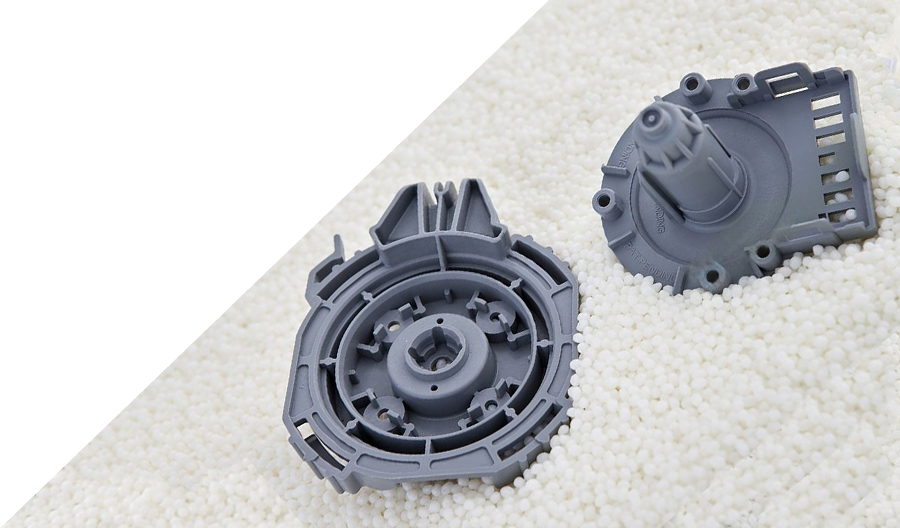

Plastic injection or bi-component moulding cold metal stamping.

Product assembly.

Objective

To constantly improve our work, investing in the professional growth of our colleagues to ensure an increasingly efficient and quality service.

R&D – technical department

From design to manufacture, our commitment to R&D is an added value that has made our services so successful. Our technical department employs highly professional mechanical engineers and a cutting-edge CAD CAM system for workshop machining.

Production

Our company’s agile, flexible structure seamlessly adapts to our customers’ requirements. Our team of engineers have consolidated industry experience.

Company activities are constantly monitored to guarantee the highest level of professionalism in the service required. De Stefani & Figli srl has been certified UNI EN ISO 9001-2015 since 2003.

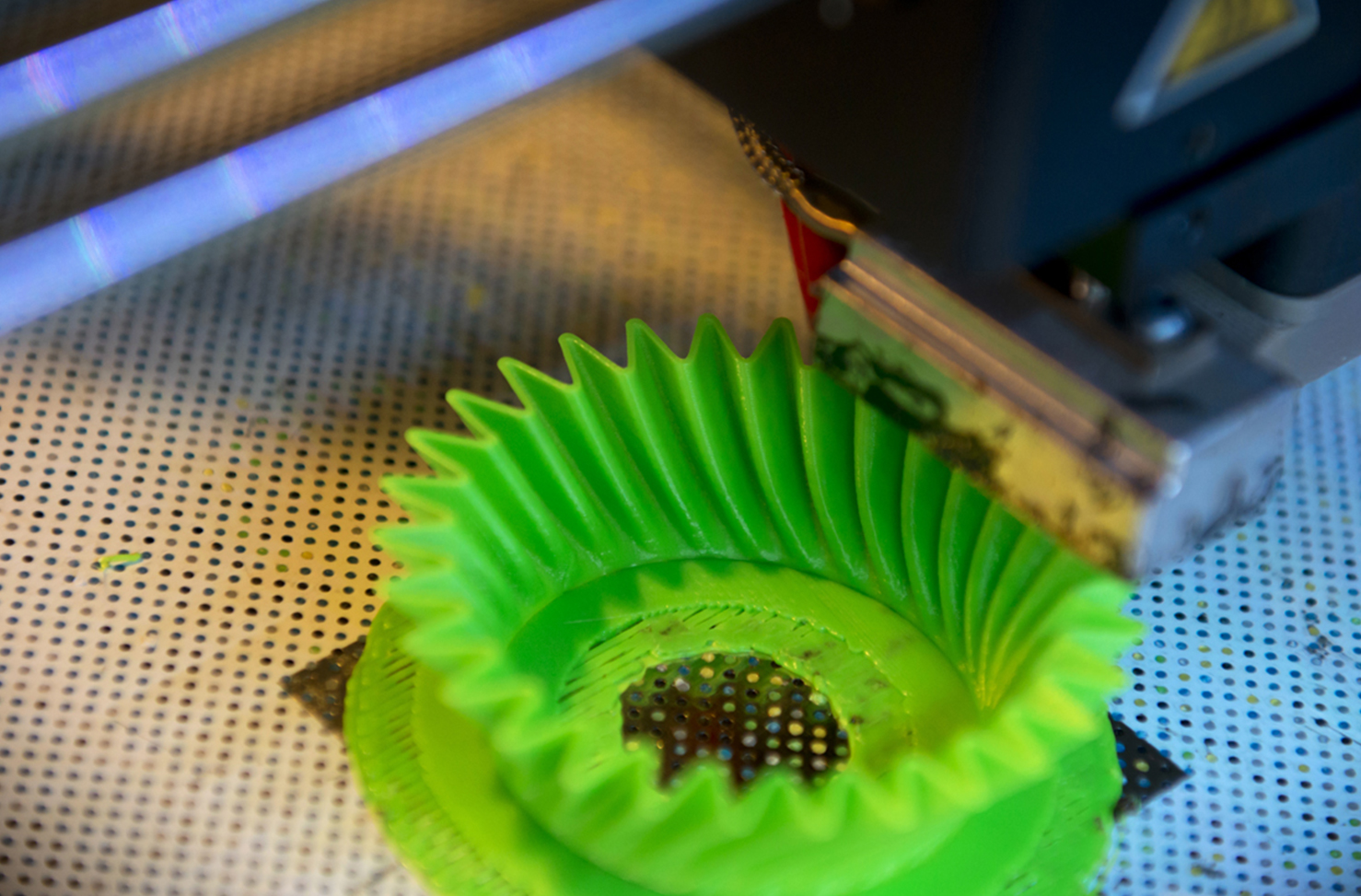

Prototyping

Rapid plastic and metal prototyping is an innovative process that allows high-quality prototype parts to be produced quickly and efficiently. This process is particularly useful for companies needing to create test parts before putting them into large-scale production.